Sheet Metal Fabrication: Crafting Versatile Metal Components

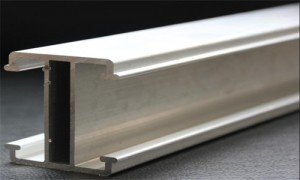

Sheet metal fabrication involves the manipulation of thin metal sheets to create a wide array of products and components. Some common uses include:

Industrial

Machinery Parts: Components such as brackets, enclosures, and panels for

machinery and equipment.

Architectural

Elements: Decorative facades, roofing, cladding, and structural elements for

buildings.

Automotive Parts:

Body panels, chassis components, and engine parts in the automotive industry.

HVAC Systems: Ductwork, vents, and enclosures for heating, ventilation, and air conditioning systems.

Benefits of Sheet Metal Fabrication:

Strength and

Durability: Despite its thinness, sheet metal offers excellent strength and

durability, making it suitable for a range of applications.

Versatility: The ability to bend, cut, weld, and shape sheet metal allows for the creation of custom components tailored to specific needs.

Cost Efficiency: Sheet

metal fabrication is often more cost-effective than casting or forging,

especially for medium to high-volume production runs.

Stainless Steel Fabrication: The Pinnacle of Corrosion Resistance

Applications and Industries:

Stainless steel

fabrication involves working with this corrosion-resistant alloy to create

durable and long-lasting products. Here are some common applications:

Kitchen Equipment: Sinks, countertops, cabinets, and appliances in residential and commercial kitchens.

Medical Devices:

Surgical instruments, equipment components, and hospital fixtures.

Architectural

Design: Handrails, balustrades, signage, and decorative elements in buildings.

Chemical and Food

Processing: Tanks, containers, pipes, and equipment for industries requiring

corrosion resistance.

Benefits of Stainless Steel Fabrication:

Corrosion

Resistance: Stainless steel's chromium content provides exceptional resistance

to corrosion, rust, and staining.

Hygienic

Properties: Its smooth surface is easy to clean and maintain, making it ideal

for medical and food processing applications.

Strength and Aesthetic Appeal: Stainless steel combines strength with an attractive, modern appearance, enhancing both functionality and visual appeal.

Precision Craftsmanship and Modern Techniques

CNC Machining: Computer Numerical Control (CNC) machines play a crucial role in sheet metal and stainless steel fabrication. These automated tools ensure precise cutting, drilling, and shaping of metal components according to exact specifications.

Welding and Finishing: Skilled welders employ various welding techniques such as MIG, TIG, and spot welding to join metal pieces seamlessly. Additionally, finishing processes such as polishing, grinding, and powder coating enhance the appearance and durability of fabricated metal products.

Conclusion

Sheet metal fabrication and stainless steel fabrication are vital processes that shape the modern world around us. From industrial machinery to architectural marvels and everyday appliances, these techniques bring versatility, durability, and aesthetic appeal to a wide range of products. As technology advances and craftsmanship evolves, the possibilities for creating innovative and functional metal components continue to expand.

For those in need of high-quality sheet metal and stainless steel fabrication products, Z Linkage offers a range of precision-crafted solutions. Explore their products to discover the craftsmanship and precision that go into every piece of metalwork.

Call to Action:

Ready to elevate

your projects with precision-crafted metal components? Visit Z Linkage to

explore their sheet metal and stainless steel fabrication products, and embark

on a journey of durability, versatility, and unmatched quality.

Comments

Post a Comment