Precision and Innovation: Unveiling the World of Plastic Molding Manufacturing

Plastic is essential to manufacturing due to its adaptability, durability, and unlimited possibilities. Innovation and precision are seen in plastic mfg, a major product-making process. ZLINKAGE METAL&PLASTIC PLUS, an industry pioneer, explores plastic molding manufacturing's complexities and sets new standards.

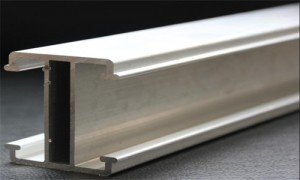

Making Plastic Molds

Technology, design, and engineering precision are crucial to plastic molding manufacturing. ZLINKAGE METAL&PLASTIC PLUS masters this craft, paying meticulous attention to every step from prototype design to mass production. The result? Perfect plastic goods that combine style and utility.

Plastic molding manufacturing is

used in many industries due to its benefits. Plastic molding's versatility,

cost-effectiveness, and durability are unmatched. Complex designs and detailed

patterns can be created using this technology for a variety of product demands.

Precision and QA

Plastic molding at ZLINKAGE METAL&PLASTIC PLUS relies on precision engineering. From raw material sourcing to assembly, quality is checked at every step. Each product fulfills strict quality standards and client expectations due to the commitment to perfection.

Applications in many sectors

Plastic molding is used in many industries. Plastic can be used in many goods, from car parts to consumer electronics, medical gadgets, and household items. Due to its lightweight, durability, and design flexibility, it is suitable for many industries.

Innovative, sustainable solutions

Beyond utility, plastic molding manufacturing is sustainable. Recycling plastic and using eco-friendly production methods make manufacturing greener. Additionally, material and process innovation propels the sector toward more sustainable and efficient solutions.

OEM Collaboration and Capabilities

Collaboration is something that ZLINKAGE METAL&PLASTIC PLUS is committed to, and they are aware of how important it is to fulfill the specific requirements of your customers. OEM capabilities enable customized plastic molding solutions for projects. Collaboration guarantees client pleasure and project success, whether it's a specific prototype or mass manufacturing.

Conclusion: Plastic Molding Manufacturing Redefining Possibilities

When it comes to creativity, precision, and versatility, the manufacturing of plastic molding represents the summit of both. ZLINKAGE METAL&PLASTIC PLUS is a leader in this industry, demonstrating how plastic can create functional, durable, and attractive goods.

In addition to improving the quality of their products, firms that take use of the potential offered by plastic molding manufacturing not only contribute to the development of environmentally responsible manufacturing methods but also establish new standards for the industry as a whole.

Comments

Post a Comment